Design files:

Face Shield documentation:

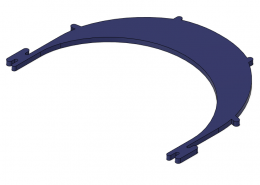

Stingray Face Shield Headband

Design ID: Stingray Face Shield Headband V-01

Description

This is a face shield designed for easy and rapid manufacture. This is a face shield designed for easy and rapid manufacture. The design is listed with the Therapeutic Goods Administration of Australia classified as GMDN Code 64779 and listed under ARTG 337217.

The face shield was designed with the intention of providing health care workers with an interim supply of face shields. It can be cut from a sheet via 2D processes such as laser or waterjet cutter, or 3D printed. Using a waterjet cutter, it and has been tested with 4.5mm polycarbonate (see the face shield Design Summary and Instructions for Use for further detail).

This is a design was inspired by Lynxter and tailored for 2D cutting but can be 3D printed too. This will allow those with 2D cutting assets (such as laser/waterjet cutters or routers) to have a tested design for production (see Testing Report). This was designed by members of the Advanced Manufacturing Alliance @ CDU in consultation with local healthcare professionals. Approximately 100 can fit on a 2.4×1.2m sheet and take 1.3 min each to cut on a waterjet.

Features

Protection:

- Overhead droplet protection: Filled in headband

- Additional wrap-around droplet protection: Altered rear shield mounting points slightly towards sagittal midline of head increasing wrap around distance and decreasing gap between shield and side of face.

Production:

- Option of 3D printed geometry or 2D profile for 2D cutting. 2D cutting allows for scalability, faster production, and use of more durable materials and less pores or cavities associated with layered production in 3D printing.

- 3D printing option allows for flexible on-site manufacturing.

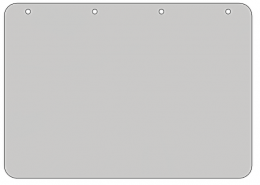

- Shield attachment point spacing enables use of EU/AUD standard 4-hole punch for cutting shield (4x 6mm holes, 80mm spacing), enables flexible on-site manufacturing.

- Shield attachment point spacing enables use of A4 sized shields (210x297mm) so that commonly available transparencies and other plastic sheet material are suitable. Enables flexible on-site manufacturing.

- Flexes onto the head of the wearer. For some people the pressure generated may be uncomfortable, in which case the CRESCENT visor is recommended.

Benefits for Sterilisation:

- Material able to withstand higher temperatures associated with sterilisation: Headband made from solid sheet polymer (Polycarbonate or PETG recommended)

- Less pores or cavities which are associated with layered production in 3D printing: Headband made from solid sheet polymer (Polycarbonate or PETG recommended)

Fit and use:

- Reusable provided it is sterilised correctly and meets basic quality checks prior to re-use (see IFU)

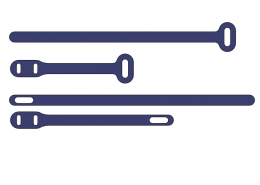

- Interchangeable components- Simple to replace headband/shield/strap if it becomes damaged during use or cleaning.

- Mounting points for overhead strap if required

Specification

- See Design Summary document

- Cut from 4.5mm plastic sheet. We have used polycarbonate which was successful, but other materials such as PETG are suitable.

- For 3D printing PETG is recommended and PLA is acceptable when PETG is not available.

- If intending to wear for a long period it is recommended to use a sweat band or other cushioning device to increase comfort.

Attribution

Design modifications by:

- Matt Harbidge and Rebecca Murray

Original design by:

- Lynxter located HERE.

Licence:

- This work is licensed under a Creative Commons Open COVID License – Patent and Copyright (OCL-PC) 1.1.

Citing:

- Reference as: “Stingray Face Shield Headband” by AMA is licensed under OCL-PC 1.1

Leave a Reply

Want to join the discussion?Feel free to contribute!